- Thread protector

- Offshore Conductor

- Offshore Conductor Joint

- Clamp on thread protector

- Inflatable thread protector

- Stabbing Guide

- Drift Gauge/Drift/Pipe Drift

- Bumper

- Racking System/Wine Racking

- Dies/ insert button/ slips dies

- API Coupling

- Pup Joint

- API 5CT Tubing

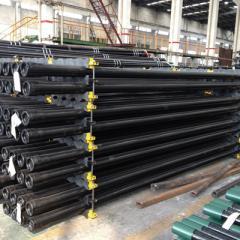

- API 5CT Casing

- Premium Connection

- Super 13Cr Series tubing and casing

- High Collapse Casings

- Ultra Strength Casing

- Coupling Stock

- Economical Corrosion Resistance series

- Tube for Perforation Gun

- Vacuum Insulated Tubing(VIT)

- H2S Corrosion Resistance Tubing and Casing

- Pipe Materials for down hole tools

- Slotted Screen Pipe

| Standard | API 5CT and Technical documents |

|

Grade |

N80Q, 80SS, 110SS, BG80H, BG110H |

|

Outer tube x inner tube |

139x101, 139x88, 114x76, 114x62, 88x50, 73x40 |

|

Insulating Grade |

B, C, D, E |

|

Place of Origin |

China |

|

Application |

heavy oil, to reduce heat loss of steam injection process |

|

End Type |

BTC, NUE, EUE, USS |

|

Packing |

wood rack or steel-plastic braket |

Steam injection is the development of heavy oil resource economic effective method.

In order to reduce heat loss of steam injection process and protect casing, usually by Vacuum Insulated Tubing(VIT).VIT generally uses double concentric tube, in the two layers of annulus inside pack insulation materials, and the pipe ends sealed to ensure good insulating properties.

1. Reduces the heat loss, certainly the steam quality and the depth of steam injection can be increased.

2. Minimizes heat stress on casing and cement mantle, protect the casing from damage by high temperature.

3. During oil production it will provide superior insulation and greatly reduce the loss of heat energy.

Character of Pre-Stressed Vacuum Insulated Tubing

1. The pre-stress will compensate the tubing expansion caused by temperature difference between the inner and the outer tubes so as to ensure reliable operation under high temp.

2. Gas absorbing materials are packed inside the annulus to clean up harmful gas and

maintain good insulating property whilst in service.

3.Integrated application of heat insulation technology, contains vacuum, heat reflection, heat convection block , ensure super heat insulation performance ofthe insulated tubing.