The principle of oil pipe coupling: oil pipe coupling is a device used to connect oil pipes, usually used to connect two oil pipes with different diameters. It has good durability, can withstand high pressure, and has good sealing performance. Tubing couplings usually consist of two parts: one is an internally threaded part and the other is an externally threaded part. The internally threaded part is usually made of steel or stainless steel, and the externally threaded part is usually made of rubber, plastic or metal. The function of the oil pipe coupling is to connect two oil pipes of different diameters together so that they can withstand high pressure. In addition, it can effectively seal the connection, so as to avoid oil leakage. Therefore, oil pipe couplings play an important role in oil transportation.

The role of oil pipe couplings: oil pipe couplings play an important role in oil transportation. They can help us connect large oil pipes together, making the whole transportation process smoother. The oil pipe coupling price points out that in addition, the oil pipe coupling also has a certain durability and can withstand a certain pressure, making the entire transportation process safer.

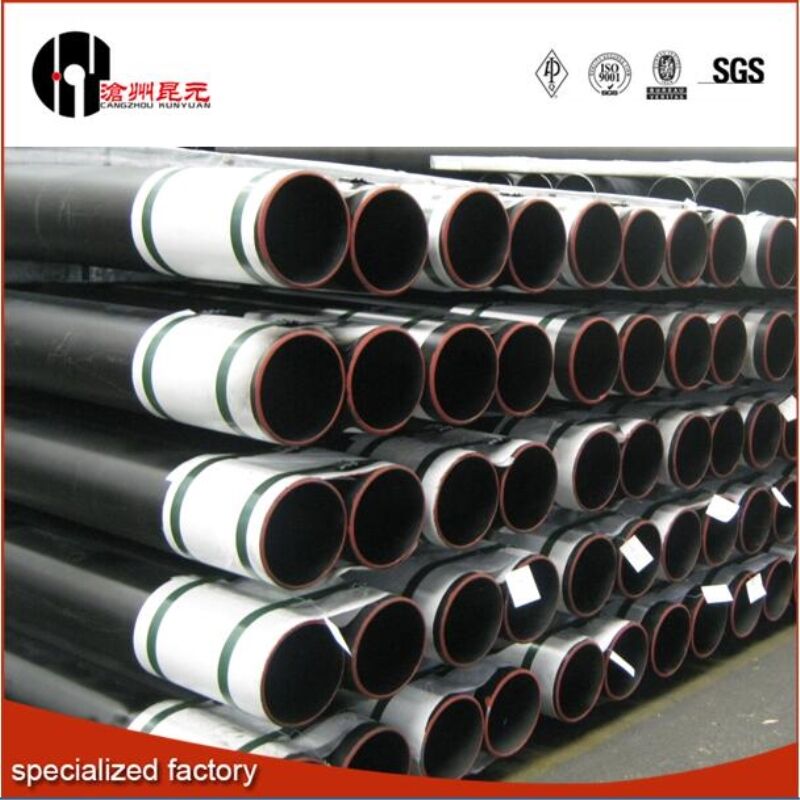

Types of Tubing Couplings: A tubing coupling is a device used to join two pipelines together. It is usually made of metal and has a seal to prevent leaks. Oil pipe couplings are mainly used to connect two oil pipelines of different materials, or to connect two oil pipelines of the same material. When transporting oil, generally steel or stainless steel oil pipes are used. The stainless steel oil pipe has the advantages of good corrosion resistance and high strength, and can well guarantee the safety of transportation. However, due to the high cost of stainless steel, steel tubing is still the option in some cases. When using steel tubing, in order to ensure its durability and service life, a protective layer must be added. Commonly used protective layers include plastic, rubber or metal. Metal protection is the most commonly used method at present, because it can well protect the metal surface from corrosion. Typically, metal cover is applied by welding a stainless steel electrode to the metal surface. Using this method can well avoid the corrosion problem of the metal surface.