NEWVAM tubing pup joint connection is a kind of fitting often used in industrial pipeline connection.

And the more common ones are pup joint-threaded connections, which can be divided into double-end outer wires, single-end outer wires, and flat-end outer wires. In addition, there will be pup joint-circuit connections with flange connections.

NEWVAM tubing is pup joint-segmented tubing. Compared with tubing, only the total length is different, and the rest are the same. The total length is: 0.25m, 0.5m, 1m, 1.5m, etc., which are used to assemble downhole string. Tubing pup joint-circuit, usually refers to the tubing pup jointer than the total length of R1. The total length is usually 0.3 meters-6 meters. And the customary 1FT-20FT in foreign countries. The basic model specifications, steel grade, and operating environment are the same as ordinary tubing.

Our company’s tubing pup joint connection is strictly required to be produced

in accordance with the Petroleum Association. The raw and auxiliary materials

are selected from large-scale enterprise pipes that have passed API

certification. The steel grades include J55, N80, L80, and P110. The thread

processing uses imported CNC milling machines. Part of its total length fully

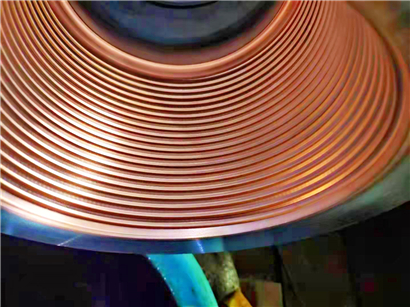

complies with API standards and is close to zero error. The surface treatment

of galvanizing and copper plating are determined by the customer. Thread gauge,

hardness tester, non-destructive magnetic particle abrasion tester, and a set

of thread single-item measuring instruments such as taper, pitch, tooth height,

and tooth shape, effectively ensure the product's compliance rate.